Invented by the Military for the Military

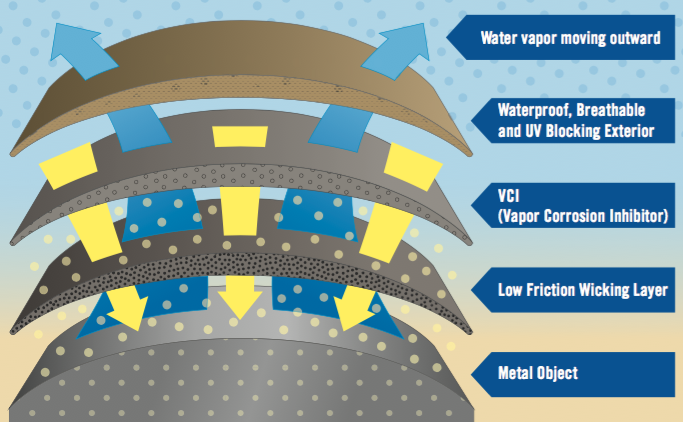

Envelop is a custom fit cover that can be used on nearly any asset. The material is waterproof so that liquid water cannot permeate the cover from outside, however, water vapor can pass thru the cover. The breathable nature of the cover prevents the "greenhouse" effect while reducing condensation and keeping the metal surface dry. Most Envelop covers also mitigate corrosion thru the use of a Vapor Corrosion Inhibiting (VCI) layer which emits ions that bond with water molecules preventing them from bonding with metal. This stops electron transfers thereby preventing corrosion. The ions do not bond with metal or optics nor do they affect electronics in any way.

The patented technology that makes Envelop so effective is the combination of breathability and VCI. Moisture vapor transmission, the measure of breathability, alone will not lower humidity below corrosive levels inside the cover if the ambient humidity is at a corrosive level. Without VCI, a cover has no ability to fight corrosion without lowering relative humidity under the cover to a level that is less than ambient. The way to most effectively protect an asset is to provide a cover with a vapor transmission rate that is high enough as to not cause a greenhouse effect while also incorporating a VCI for those cases where humidity is at a corrosive level. Envelop Protective Covers are the only product available that combines high moisture vapor transmission with a VCI.

The Envelop solution is easy to use, similar to traditional covers used by the military, however, Envelop's cover technology has been shown to reduce corrosion by up to 95%. In addition to corrosion protection, Envelop will protect against moisture, sand, dirt, UV, airborne pollutants, heat, cold, FOD impact, and wind.

With Envelop

Without Envelop

Key Features

Breathable:

Moisture vapor transmission rate (MVTR) of 3,000 g/m²/24 hours allows water vapor to escape while preventing liquid water from entering. This prevents the greenhouse effect and reduces condensation, keeping the metal surface dry.

Vapor Corrosion Inhibitor:

VCI layer which emits ions that bond with water molecules preventing them from bonding with metal. This stops electron transfers thereby preventing corrosion. The ions do not bond with metal or optics nor do they affect electronics in any way. VCI weave is inert and lasts for over five years. Reduces formation of corrosion by up to 95%.

Non-Porous:

The waterproof membrane cannot be clogged by microscopic sand, dirt, and dust fragments. This prevents diminished breathability over time and eliminates the need to regularly clean the inside of the cover.

Durable:

Robust materials perform exceptionally well in tensile strength, seam strength, tensile elongation, tear resistance, puncture, and abrasion testing. The materials are resistant to degradation from grease, oils, lubricants, and cleaning agents. Cover life expectancy is over five years for ground applications with some exceeding eight years.

Waterproof:

Water, rain, and precipitation will not penetrate the cover. Passes the water column at over 13, making the cover impervious to even the most severe driving rains.

UV Resistant:

Blocks 99.9% of UVA and UVB rays helping to preserve paint, coatings, wiring, grommets, and other sensitive components. Also keeps temperatures under the cover within twelve percent of the ambient temperature.

Mold & Mildew Resistant:

The materials scored zero on Fungal resistance tests, meaning they are not conducive to mold, mildew, and fungus growth. This protects operators from exposure to potentially dangerous substances.

Easy to Maintain:

The cover can be washed using soap and water and isopropyl (rubbing) alcohol. The materials will not absorb water ensuring ease of use for operators.

Design Process

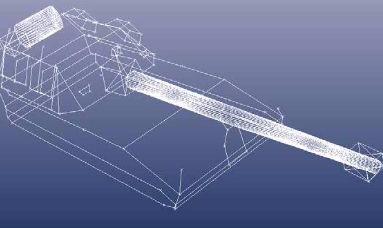

The design process begins with an engineer capturing inputs for the design, then converting them to CAD files. This process reduces the time required from concept to finished product by increasing the accuracy of the initial design and including the necessary functionality in early-stage prototypes. Prototypes are fitted with Soldiers and Marines to ensure the designs are favorable for the operating environment in which they will be deployed. Weight, accessibility, operational firing capability, packability, ease of installation/removal, and storability are just a few of the dimensions which are optimized when covers are designed. Lastly, all feedback rendered from the end-users is incorporated to designs to help war-fighters maximize the benefit they receive from their Envelop Protective Cover.

How It Works

4-Layer System

- Hydrophobic wicking layer pulls moisture from surface of equipment.

- Non-porous membrane eliminates intrusion of corrosion causing micro Sulfur Dioxide and Chloride molecules, while preventing clogging to maintain high breathability rates throughout the life of the cover.

- Vapor corrosion inhibitor (VCI) releases ion that prevents oxygen molecules from bonding with equipment, reducing corrosion up to 90%.

- Durable outer material is waterproof, breathable, and 100% UV resistant—allows moisture to evaporate outward, thereby preventing the greenhouse effect.

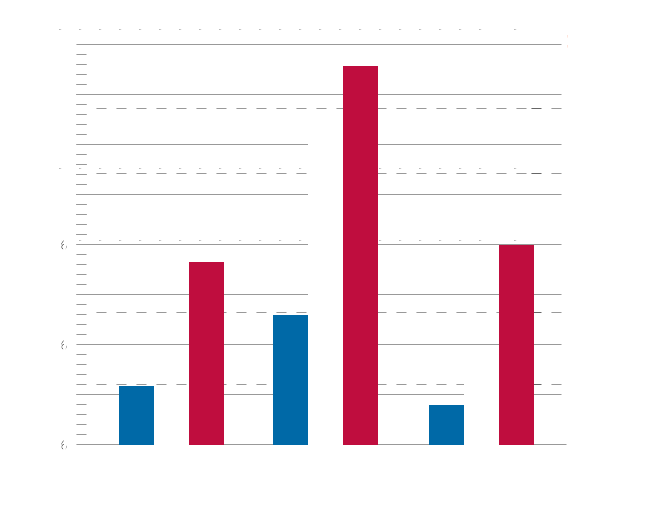

Mechanical Testing Review

Cover Mechanical Properties Comparison

Conducted by Independent Laboratory – 2013

Testing Categories

- Tearing strength

- Breaking strength

- Abrasion cycles to failure

- Puncture resistance

- Seam strength

Technical Specifications

| Specification | Metric | Notes |

|---|---|---|

| Vapor Corrosion Inhibitor (VCI) | Minimum Effective Lifespan Greater than 5 Years | |

| Moisture Vapor Transmission Rate (MVTR) | Minimum 3,000 g/m²/24 hours | ISO 15496 |

| Wind | Secure up to 75 mph | Analysis |

| Waterproof | Minimum 10m Hydrostatic Column | ISO 811 |

| Thermal Protection | Maintain Internal Temperature within 112% of Ambient | |

| Color Fade after Accelerated Weathering | Less Than 2 NBS Units after 750 hours | MIL-DTL-53039 |

| Glossiness | Less Than 5 Units at 60 Degrees | ASTM D523 |

| Tensile Strength (Warp Direction) | Minimum 350 lbs/in² | ASTM D5035 |

| Tensile Strength (Fill Direction) | Minimum 300 lbs/in² | ASTM D5305 |

| Seam Strength | Minimum 30 lbs/in | |

| Tensile Elongation | Breaking Point Minimum 25% | ASTM D5035 |

| Tear Resistance (Warp Direction) | Minimum of 20 lbs | ASTM D2261 |

| Tear Resistance (Fill Direction) | Minimum of 23 lbs | ASTM D2261 |

| Abrasion | No Defect After 19,000 Cycles using CS-10 Wheel with 500 g Load | ASTM D3884 |

| Bursting Strength/Puncture Resistance | Minimum 700 lbs of Force | ASTM 4833 |

| Resistance to Accelerated Aging | No Increase in Softness, Stiffness, Tackiness, or Brittleness, Nor Color Change when Exposed to 160 °F for 14 Days | ASTM D3045 |

| Wet Weight | Maximum Weight Gain of 2oz per yd² 2 Hours After Saturation | ASTM D3776 |

| Hazardous Materials | Non-Toxic to Skin, Eyes, or Epidermis | CFR, Title 40, Sections 798.4100, 798.4470, 798.4500 |

| Odor | Maximum Rating of 2 | SAE J1351 |

| Flexibility | Usable and Packable at Temperatures Between -40 °F and 125 °F | |

| UV Radiation | Cover Meets MVTR Requirement, 10,000 Cycles of Abrasion Testing, Maintains 60% of Strength Characteristics after 1,000 Hours of UV Exposure | AATCC TM 186 |

| Material Degradation Resistance | Maintains Waterproof and Tensile Strength Requirements after Exposure to WTR Grease, Grease, Molybndium Disulfide, Hydraulic Fluid, Brake Fluid, Cleaner, and Lubricant | |

| Corrosion Reduction | Reduces Corrosion Formation by a Minimum of 90% | Vapor Corrosion Inhibitors (VCI's) actively reduce corrosion at high levels of relative humidity. ASTM D2136 |

| Resistance to Low Temperatures | Pass/Fail | |

| Resistance to High Temperatures | Pass/Fail | |

| Mildew Resistance | Rating of 0 | ASTM G21 |

| Flame Resistance | Does Not Melt at Temperatures up to 219.2 °F. Will not Ignite at Temperatures up to 752 °F |